Are you aware that leakage drives up the energy costs in production? However, leaks often remain undetected for long periods, as one mostly cannot see or hear them. Such undetected leaks slowly become real cost drivers. Remedying leaks provides the highest savings potential in the field of compressed air supply.

Small cause - large effect

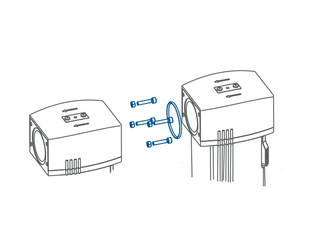

Small cause - large effect. Even small leaks can make a big contribution to the costs for compressed air. In total, leakage rates of 30% are not uncommon. In times of rising energy prices, high sums of money therefore “go up in smoke” very quickly. The remedy here is the small and easy-to-use METPOINT LKDLeak Detector. If it is utilised, then the leaks in the system can be located in a short time. Maintenance is therefore targeted accurately and possible at short notice. The METPOINT LKD uses a physical characteristic for this purpose. As compressed air escapes, the gas molecules cause friction along the pipework wall. This friction in turn generates a noise in the ultrasonic frequency range.

Request a Quote